Our Products

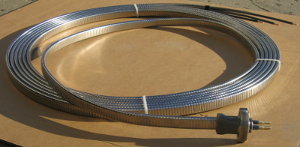

Motor Lead Extensions (MLE)

Description

Motor Lead Extensions are used to supply power to ESP motors in oilfield applications and are an integral part of the system. Wadi El-Gattar ESP MLEs are reliable and designed to last, we supply only top quality components and KELB cable during manufacturing.

Specification

| Temperature | 230C / 450 F |

| Pothead Flange | Ni-Resist 2 material epoxy sealed |

| Conductor AWG | #4 (540/562 Series) or #6 (456/375 Series) |

| Conductor | Three phase solid copper conductors |

| Kapton | Two layers of 50% overlapped Polyimide tape are applied to the conductors to facilitate high thermal and electrical performance |

| EPDM | A high-quality EPDM compound is bonded to each Kapton covered conductor. EPDM is formulated to provide high dielectric strength and low swell characteristics in the presence of oil and gas |

| Lead | A continuous, impervious, fatigue and corrosion resistant lead sheath is extruded over the insulation to provide excellent protection against oil, chemicals and gases and insulation decompression. |

| Braid | A synthetic braid, applied with full coverage over the lead sheath, provides additional mechanical reinforcement and hoop strength |

| Armor | 50% lapped, Monel, Stainless or Galvanized armor. |

| Testing | Pressure: Cables are tested at intervals from 5 through to 40 PSI. Continuity: Ensure there are no break in Armor. Hi-Pot: Cables are tested to CSA standards for any electrical fault |